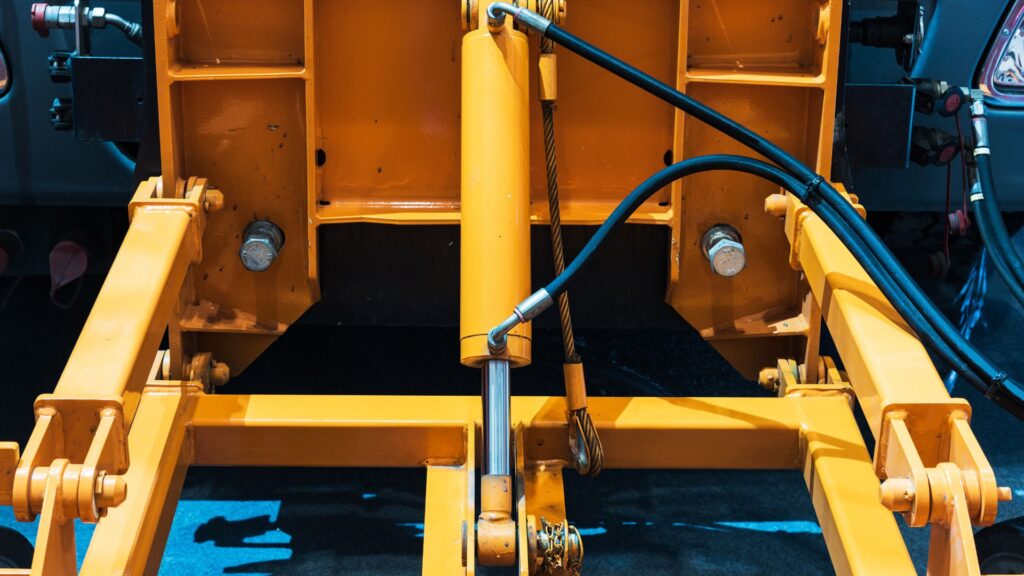

Hydraulic system maintenance ensures optimal performance, longevity, and safety by preventing breakdowns and extending equipment life. Reliable hydraulics are essential for efficient and safe operation. At CT Hydraulics, we understand the importance of proactive hydraulic system maintenance. By being aware of the key signs that your system needs attention, you can avoid potential downtime and ensure your equipment continues to operate smoothly.

Here are the top 5 signs that your hydraulic system needs maintenance:

1. Reduced Performance:

- Symptoms: Is your equipment performing slower than usual? Are cylinders extending or retracting with sluggishness?

- Cause: Reduced performance can indicate several issues, including low hydraulic oil levels, worn-out components (cylinders, pumps), or contaminated oil.

- Action: Check hydraulic oil levels and top up if necessary. Schedule a maintenance inspection to diagnose the root cause and identify any necessary repairs.

2. Unusual Noises:

- Symptoms: Are you hearing grinding, whining, or banging noises coming from your hydraulic system?

- Cause: Unusual noises are often a telltale sign of internal wear and tear on components like pumps, valves, or cylinders.

- Action: Don’t ignore these sounds! Shut down the equipment immediately to prevent further damage. Contact a qualified hydraulic repair specialist in South Africa, like CT Hydraulics, for troubleshooting and repairs.

3. Excessive Heat:

- Symptoms: Is your hydraulic system running hotter than usual? Are there any hot spots around components?

- Cause: Excessive heat can be caused by a variety of factors, including low oil levels, a clogged filter, or a failing pump. Overheated systems can lead to degraded oil performance and component failure.

- Action: Check oil levels and inspect for leaks. Consider replacing the filter if you suspect it’s clogged. If the overheating persists, contact a hydraulic repair professional for diagnosis and repairs.

4. Visible Leaks:

- Symptoms: This one is fairly self-explanatory! Are there any leaks of hydraulic oil from hoses, cylinders, or other components?

- Cause: Leaks indicate worn or damaged seals, loose connections, or cracked hoses. Left unattended, leaks can lead to significant oil loss, contamination, and system failure.

- Action: Don’t operate your equipment with leaks! Shut down the system immediately and identify the source of the leak. Depending on the severity, you may need to replace seals or hoses, or contact a hydraulic repair specialist for assistance.

5. Erratic Control:

- Symptoms: Are you experiencing difficulty controlling your equipment’s hydraulic functions? Is there a lack of precision or jerky movements?

- Cause: Erratic control can be caused by air in the system, worn components (valves, cylinders), or a malfunctioning control system.

- Action: This can be a safety hazard. Shut down the equipment and consult a hydraulic system troubleshooting expert to identify the cause and ensure safe operation.

Hydraulic System Maintenance Checklist:

Here’s a handy table to keep track of your hydraulic system maintenance:

Task | Frequency |

Hydraulic Oil Level Check | Daily |

Visual Inspection for Leaks & Damage | Weekly |

Filter Replacement | As per manufacturer’s recommendation (typically every 3-6 months) |

Hydraulic Oil Analysis | Annually |

Comprehensive System Inspection | Every 1-2 years |

Don't Wait Until It's Too Late!

By addressing these signs early on, you can prevent costly downtime, extend the lifespan of your hydraulic system, and ensure the safety of your operators. Proactive hydraulic system maintenance can significantly reduce the risk of unexpected breakdowns, minimising disruptions to your operations and saving you money in the long run. Investing in regular maintenance is an investment in the productivity and reliability of your equipment.

Call to Action:

At CT Hydraulics, we offer a comprehensive range of hydraulic system maintenance and repair services throughout South Africa. Our team of experienced technicians can help you diagnose and address any issues with your hydraulic system, ensuring optimal performance and reliability.

Contact us today and keep your equipment running smoothly!